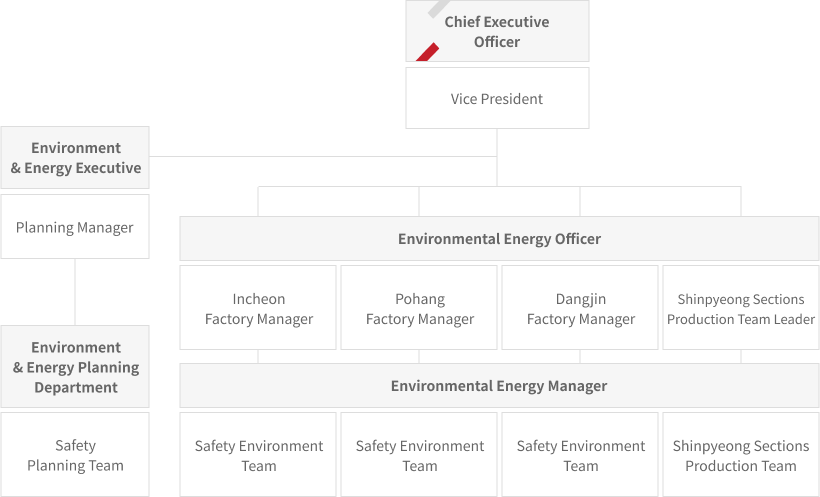

Dongkuk Steel Mill Co., Ltd. practices customer satisfaction and management of human focus on the basis of its management ideology, ‘to contribute to cultural development through Steel.’

The following will be implemented in order to ensure "an eco-friendly company leading carbon neutrality and green growth”.

One. Recognize environment and energy as essential elements of management and give priority to management activities.

One. Guarantee workers’ participation and consultation in environmental and energy management activities.

One. Comply with environmental and energy related laws and regulations and proactively respond to strengthening environmental regulations.

One. Identify potential environmental pollution risks in advance and prepare countermeasures.

One. Reduce energy consumption through the efficient use of resources and lead the way in achieving carbon neutrality.

One. Pursue social trust by strengthening communication with stakeholders.

One. Minimize environmental pollution and continuously strive to improve the environment of our local communities.

This policy is announced to all stakeholders and all executives and employees make continuous efforts to advance environmental and energy management.

10th December 2024

Dongkuk Steel Mill Co., Ltd. Representative Director / Sam Young Choi